Sushi conveyor

Sushi conveyor, known as kaiten zushi in Japanese, in which plates of sushi move around to each customer on a conveyor belt.

keywords:

Product Categories

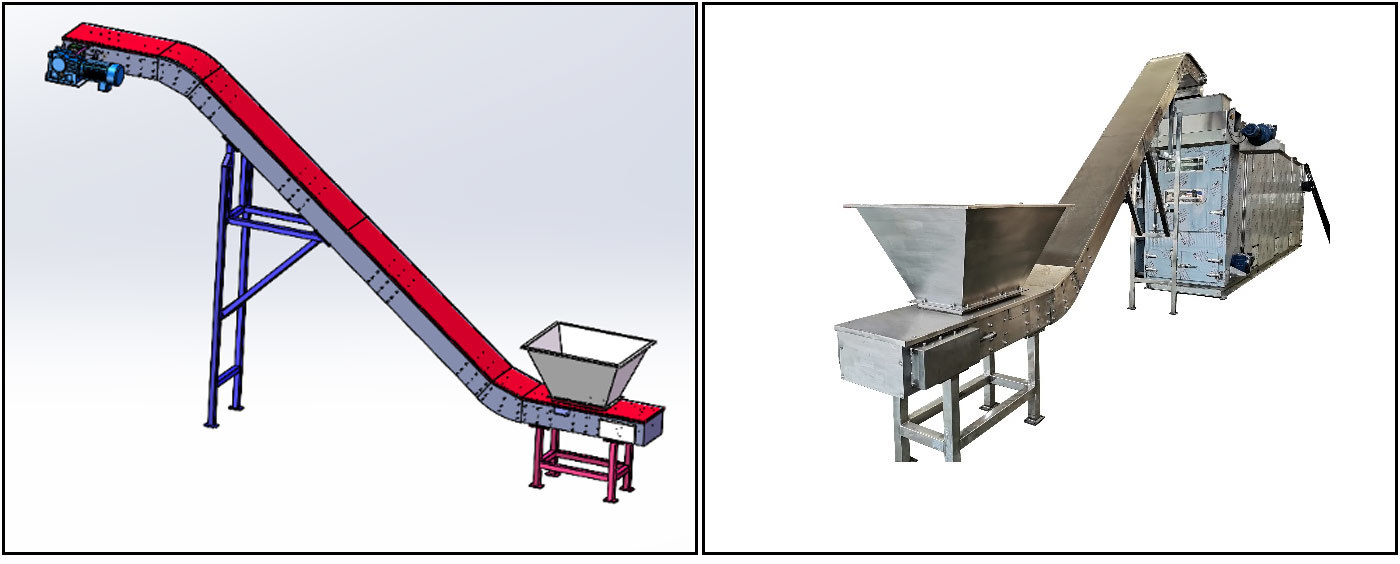

Chain Conveyor

Email:

WhatsApp:

Visits:

Introduction

Food processing and packaging require a great deal of material handling. Raw materials and finished goods need to be transported over long distances under sanitary conditions. As food production became more industrialized, manufacturers quickly realized the advantages of food conveyor systems. Operations no longer needed to wait on workers to move heavy loads to different factory locations, creating important production efficiencies. The introduction of the food conveyor belt also helped the food industry meet increasing state and federal regulations — conditions became more sanitary as food was handled less.

Teconway Scrape Conveyor Product Range:

Main structure material: PVC/PP/PU/Rubber, SUS304 stainless steel

Conveying Volume: usually less than 35m³/H.

It also can be customized according to needs.

Used for conveying: food and beverage product, grains, bulk material, food raw material, animal feed, and the like.

Production details

①Spaced Cross Members

Scarping blade/plate is made of stainless steel and nylon.

②Customized Hopper

Customize the volume as needed

Optional equipped with breaking or stirring mechanism

③ External tensioning device for easy adjusting.

④ Famous brand bearings and Gear Motor

NSK, SKF bearings/ Well-known brand gear motor/ Customer-specified brand

Advantage

1)Full Engineering Design Support

2)Advanced Equipment and Benchmark Quality

PARTNER

MASAN Group

Robinhood

NONGSHIM

Mareven Food

Kaifeng Lixing Machinery

Dongfang Noodle Machine

Qingdao Zhengya Machinery Technology Co., Ltd.

Helper

BUHLER

Baixiang Food

Related Products

The Scraper Comb is made of metal for scraping off the cutting grooves of noodle slitter. It’s also known as noodle comb, cutter comb, slitter comb.

Mesh Belt Heat Pump Sludge Dryer

When the heat pump dryer is running,the air is circulated in the closed space composed of the drying chamber and the heat pump unit. The hot air passes through the materials to take away the water, and passes through the heat pump evaporator. The low temperature refrigerant in the evaporator absorbs heat, so that the air temperature is reduced and the water is condensed and drained. The saturated air after dehumidifying is then passed through the condenser of the heat pump, where the high heat refrigerant heats the air. And, the dry hot air blows into the drying chamber again to dry the materials. During this process, the heat pump system will be running automatically by the SCM according to the set temperature.

FAQ

Related Products

Message