Mesh Belt Heat Pump Sludge Dryer

When the heat pump dryer is running,the air is circulated in the closed space composed of the drying chamber and the heat pump unit. The hot air passes through the materials to take away the water, and passes through the heat pump evaporator. The low temperature refrigerant in the evaporator absorbs heat, so that the air temperature is reduced and the water is condensed and drained. The saturated air after dehumidifying is then passed through the condenser of the heat pump, where the high heat refrigerant heats the air. And, the dry hot air blows into the drying chamber again to dry the materials. During this process, the heat pump system will be running automatically by the SCM according to the set temperature.

keywords:

Product Categories

Heat Pump Dryer

Email:

WhatsApp:

Visits:

Mesh Belt Heat Pump Sludge Dryer

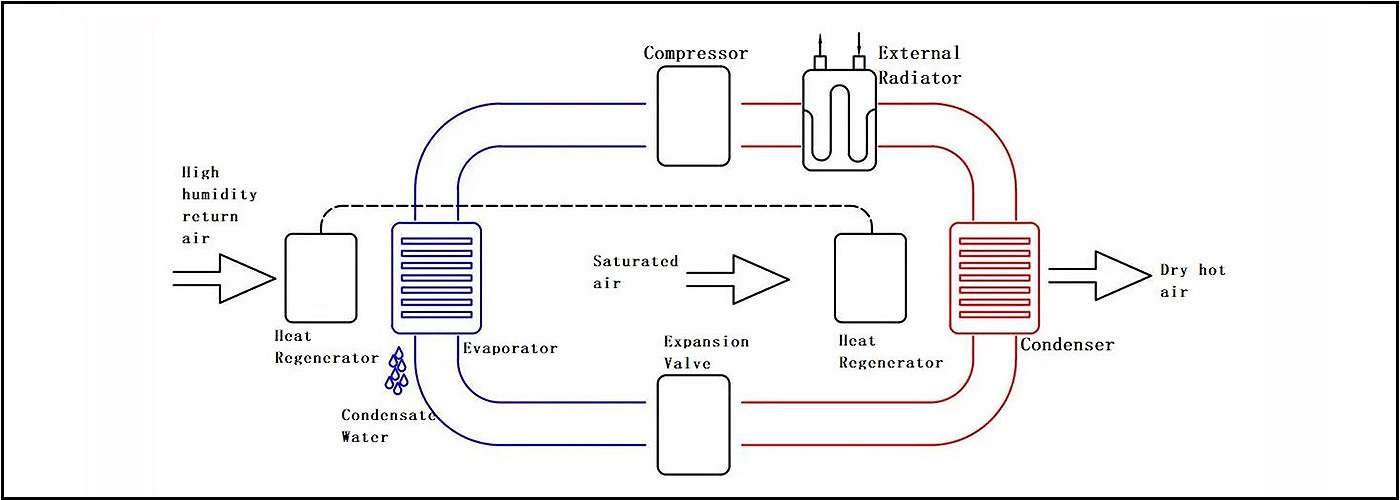

Principle of air source heat pump drying machine

When the heat pump dryer is running,the air is circulated in the closed space composed of the drying chamber and the heat pump unit. The hot air passes through the materials to take away the water, and passes through the heat pump evaporator. The low temperature refrigerant in the evaporator absorbs heat, so that the air temperature is reduced and the water is condensed and drained. The saturated air after dehumidifying is then passed through the condenser of the heat pump, where the high heat refrigerant heats the air. And, the dry hot air blows into the drying chamber again to dry the materials. During this process, the heat pump system will be running automatically by the SCM according to the set temperature.

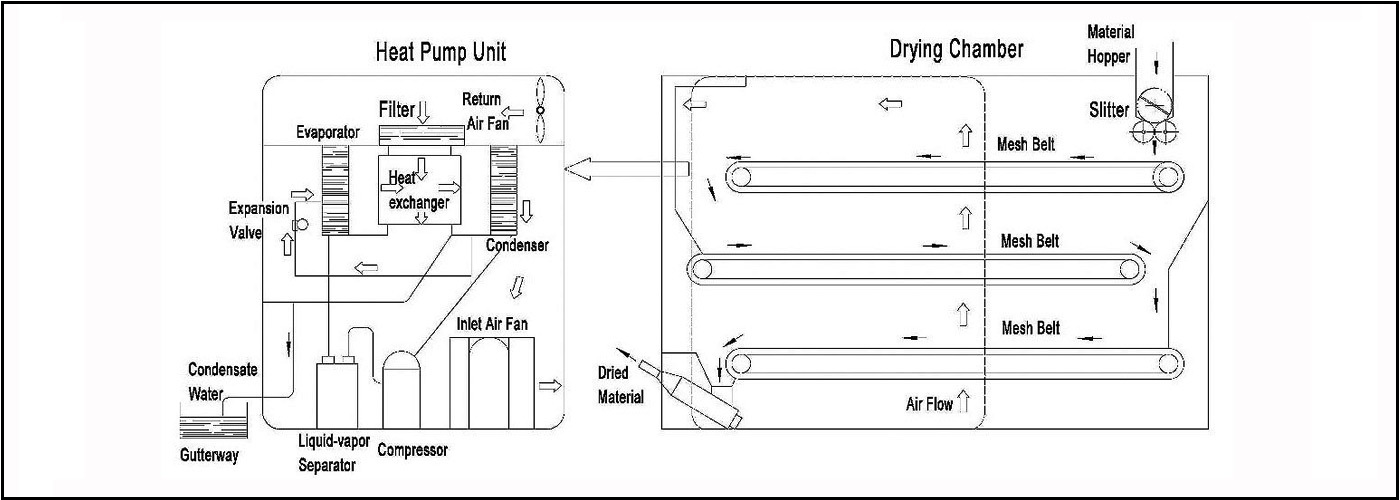

Working process of air source heat pump drying machine

The mesh belt drying machine is usually equipped with a slitter,shredder or paver at the feed port of the drying chamber, and 2-3 layers of mesh belts are equipped in the drying chamber. Materials after shredding fall onto the mesh belt and transferred by the belts from top to bottom layer by layer. The hot air entering the drying chamber passes through the mesh belts and the materials from bottom to top, takes away the water, and return into the heat pump unit for dehumidification and heating from the upper return air outlet of the drying chamber, and then back to the drying chamber.

Product Features

- Energy Efficient

- Safety and Environmental

- Intelligent Control

- Compact structure

- Reliable and Durable

- Low Operating Costs

Technical Advantage

1. Full Engineering Design Support

We provide pre-sales and after-sales technical support for your project.

2. Corrosion resistant heat exchanger

Heat exchangers such as evaporators and condensers are made of copper tubes with aluminium fins. We specially designed the structure and applied nano coating on the surface to improve the corrosion resistance

3. Well-known brand heat pump parts and electrical parts

Copeland / Danfoss compressor; Saginomiya / Danfoss EEV; Siemens / Schneider electrical components,such as VFD, AC contactor , breaker etc.

5. Large access doors

Easy for maintenance and repairment

6. Reasonable position of compressors and fans

The compressors and inlet air fans are installed outside the air duct to isolate the high temperature and humidity environment, improve reliability and prolong service life

7. Condensate water recycling and cooling technology

Fully utilizing the low temperature characteristics of the condensed water, sufficiently cools the return air, improves the dehumidification efficiency.

PARTNER

MASAN Group

Robinhood

NONGSHIM

Mareven Food

Kaifeng Lixing Machinery

Dongfang Noodle Machine

Qingdao Zhengya Machinery Technology Co., Ltd.

Helper

BUHLER

Baixiang Food

Related Products

The Scraper Comb is made of metal for scraping off the cutting grooves of noodle slitter. It’s also known as noodle comb, cutter comb, slitter comb.

Mesh Belt Heat Pump Sludge Dryer

When the heat pump dryer is running,the air is circulated in the closed space composed of the drying chamber and the heat pump unit. The hot air passes through the materials to take away the water, and passes through the heat pump evaporator. The low temperature refrigerant in the evaporator absorbs heat, so that the air temperature is reduced and the water is condensed and drained. The saturated air after dehumidifying is then passed through the condenser of the heat pump, where the high heat refrigerant heats the air. And, the dry hot air blows into the drying chamber again to dry the materials. During this process, the heat pump system will be running automatically by the SCM according to the set temperature.

FAQ

Related Products

Message