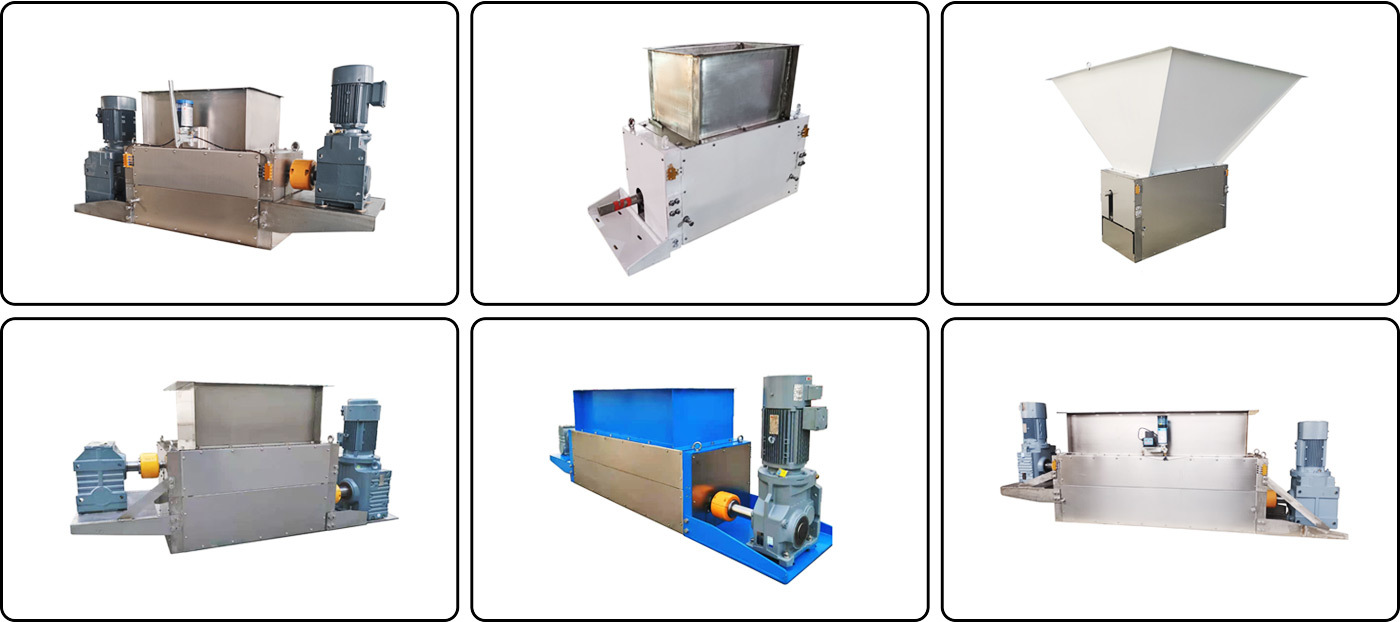

Sludge Shredder

keywords:

Product Categories

Special Cutter & Slitter

Sludge Slitter

Email:

WhatsApp:

Visits:

Built-in Sludge Slitter Device is consist of Bunker, Average Spiral Machine, Sludge Agitator and Sludge Shredder.

Working Principle:Sludge shredder is able to cut sludge cake into sludge strips, and then sludge strips spread on the drying conveyor belt. It creates uniform gaps. Hot-blast air through the gap to take away the moisture in the sludge, Thus sludge quickly dry, reduce the weigh.

Advantage:

This construction is to observe easily and to remove fault timely.

Easily detachable and Convenient operation maintenance.

Blanking evenly, drying easily and can adequately use the heat and save energy.

PARTNER

MASAN Group

Robinhood

NONGSHIM

Mareven Food

Kaifeng Lixing Machinery

Dongfang Noodle Machine

Qingdao Zhengya Machinery Technology Co., Ltd.

Helper

BUHLER

Baixiang Food

Related Products

The Scraper Comb is made of metal for scraping off the cutting grooves of noodle slitter. It’s also known as noodle comb, cutter comb, slitter comb.

Mesh Belt Heat Pump Sludge Dryer

When the heat pump dryer is running,the air is circulated in the closed space composed of the drying chamber and the heat pump unit. The hot air passes through the materials to take away the water, and passes through the heat pump evaporator. The low temperature refrigerant in the evaporator absorbs heat, so that the air temperature is reduced and the water is condensed and drained. The saturated air after dehumidifying is then passed through the condenser of the heat pump, where the high heat refrigerant heats the air. And, the dry hot air blows into the drying chamber again to dry the materials. During this process, the heat pump system will be running automatically by the SCM according to the set temperature.

FAQ

Related Products

Message