Box type heat pump sludge dryer

Low temperature heat pump sludge dryer is a kind of energy-saving and efficient sludge dehumidification and reduction equipment

keywords:

Product Categories

Heat Pump Dryer

Email:

WhatsApp:

Visits:

Box type heat pump sludge dryer

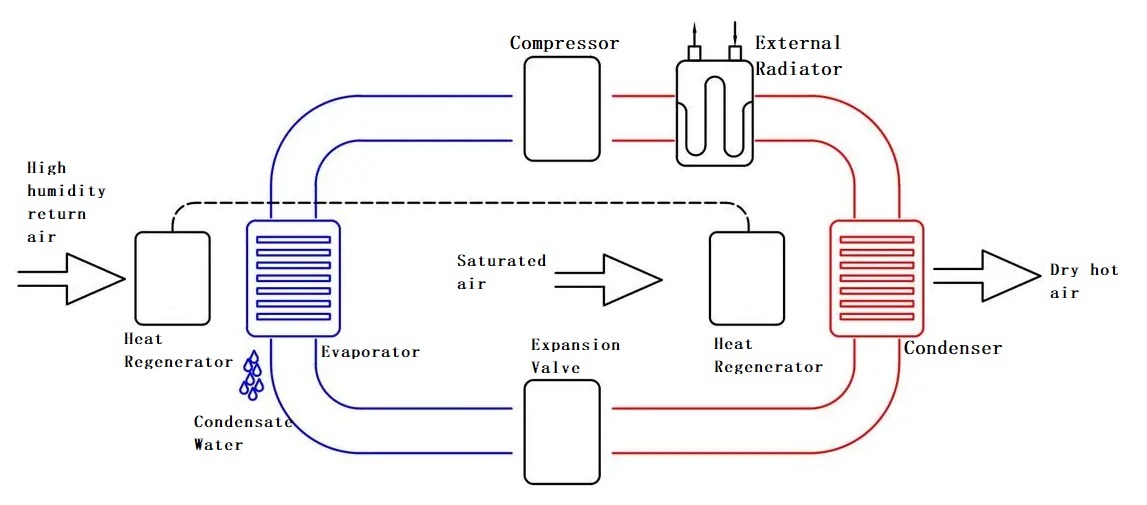

1. Principle of air source heat pump drying machine

When the heat pump dryer is running,the air is circulated in the closed space composed of the drying chamber and the heat pump unit. The hot air passes through the materials to take away the water, and passes through the heat pump evaporator. The low temperature refrigerant in the evaporator absorbs heat, so that the air temperature is reduced and the water is condensed and drained. The saturated air after dehumidifying is then passed through the condenser of the heat pump, where the high heat refrigerant heats the air. And, the dry hot air blows into the drying chamber again to dry the materials. During this process, the heat pump system will be running automatically by the SCM according to the set temperature.

2. Working process of air source heat pump drying machine

The box type drying machine, or drying chamber for short, is provided with the door to facilitate the entry and exit of the material boxes or racks. The boxes and racks are designed and manufactured according to the material characteristics and drying amount.

3. Product Features

3.1 Energy Efficient

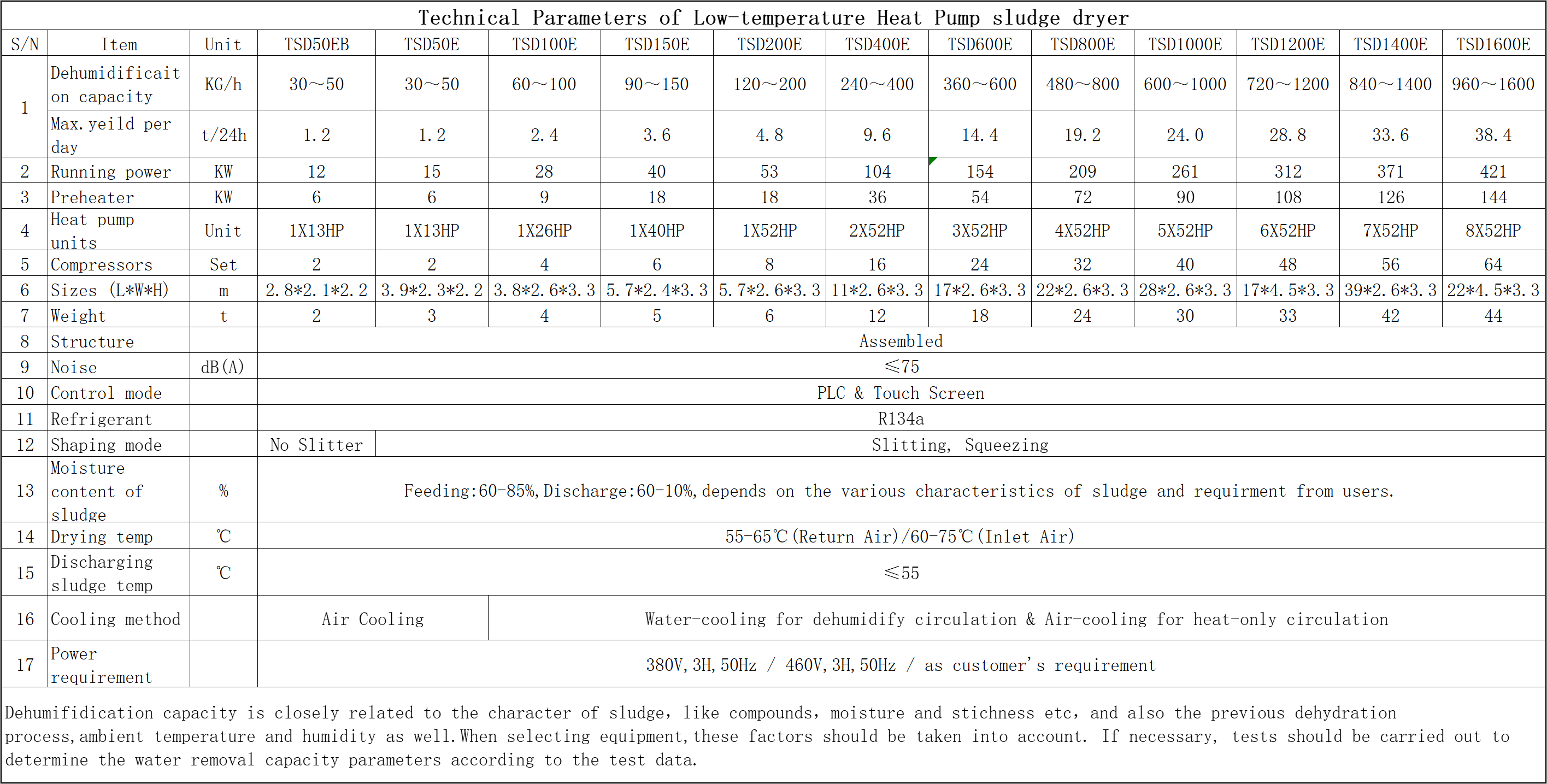

Reduce the moisture content from about 80% to 30%-10% and the weight more than 70%.

Closed insulation system, thermal energy recycling, greatly reducing dehydration power consumption

3.2. Safety and Environmental

Less than 80℃ low temperature drying, Dried material outlet temperature <55℃, avoid explosion hazard.

Closed drying chamber reduces peculiar smell discharging.

The water vapor generated in the process of drying is condensed and discharged, without secondary pollution.

3.3 Intelligent Control

Automatically control through SMC and PLC.

Parameter settings can be performed according to customers’ requirements.

Variable frequency gear motors for easy adjustment of drying time and speed.

3.4. Compact structure

Integrated designed modular structure with compact size.

Standard modules for transportation and on-site installation simply.

3.5. Reliable and Durable

Refrigerant compressors are made by brand of Coopland or Danfoss.

The heat exchangers are painted with nano-coating to improve corrosion resistance.

We have the rigorous Quality & Service system.

The machine structure frame is made of SUS304 stainless steel.

3.6. Low Operating Costs

Save water, because condensate water could be used for cooling humid air to avoid tap water consumption

Save on maintenance costs for simple maintenance and few consumables.

Save labor because of automatic control.

Save transport costs as reducing sludge mass.

PARTNER

MASAN Group

Robinhood

NONGSHIM

Mareven Food

Kaifeng Lixing Machinery

Dongfang Noodle Machine

Qingdao Zhengya Machinery Technology Co., Ltd.

Helper

BUHLER

Baixiang Food

Related Products

The Scraper Comb is made of metal for scraping off the cutting grooves of noodle slitter. It’s also known as noodle comb, cutter comb, slitter comb.

Mesh Belt Heat Pump Sludge Dryer

When the heat pump dryer is running,the air is circulated in the closed space composed of the drying chamber and the heat pump unit. The hot air passes through the materials to take away the water, and passes through the heat pump evaporator. The low temperature refrigerant in the evaporator absorbs heat, so that the air temperature is reduced and the water is condensed and drained. The saturated air after dehumidifying is then passed through the condenser of the heat pump, where the high heat refrigerant heats the air. And, the dry hot air blows into the drying chamber again to dry the materials. During this process, the heat pump system will be running automatically by the SCM according to the set temperature.

FAQ

Related Products

Message